Industrial Automatic Cleaning In Place Systems

Product Details:

- Usage Industrial

- Product Type Industrial Automatic Cleaning In Place Systems

- Material Metal

- Condition New

- Fuel Type Electric

- Cleaning Process Hot Water Cleaning

- Click to View more

Industrial Automatic Cleaning In Place Systems Price And Quantity

- 1 Unit

Industrial Automatic Cleaning In Place Systems Product Specifications

- Industrial

- Electric

- Hot Water Cleaning

- Metal

- Industrial Automatic Cleaning In Place Systems

- New

Industrial Automatic Cleaning In Place Systems Trade Information

- Cash in Advance (CID)

- 50 Unit Per Month

- 10 Days

- All India

Product Description

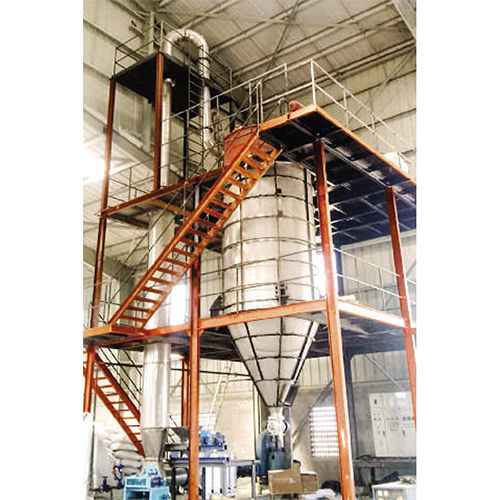

An Industrial Automatic Cleaning In Place Systems is a specialized drying system used primarily in the processing of materials where simultaneous grinding and drying are required. It can handle a variety of materials including minerals, chemicals, pigments, and agricultural products. This is typically constructed from robust materials such as stainless steel or carbon steel to withstand the abrasive nature of grinding operations and high temperatures. The design ensures efficient heat and mass transfer due to the high surface area exposure and turbulent mixing within the dryer. Industrial Automatic Cleaning In Place Systems is a versatile and efficient drying system that integrates grinding and drying operations in a single unit.

Without requiring extensive disassembly, automatic cleaning-in-place (CIP) systems are utilized to clean the inside surfaces of chambers, ducting, cyclones, pipes, vessels, equipment, filters, and related fittings. CIP systems are utilized in many different industries, such as dairy, food and herbal, probiotech, pharmaceutical, and chemical, to guarantee that equipment is hygienic and gently clean in a reduced amount of time, water, and labor.

CIP systems typically use a combination of water, chemicals, and steam OR Hot water to clean equipment. The cleaning process is typically carried out in a series of Zone wise steps, including:

a) Avoiding Manual intervention

b) Proper cleaning of the dryer

c) Saving of Water

SYSTEM DESCRIPTION

A]CLEANING CYCLE -1 : CIP for Drying Chamber

B] CLEANING CYCLE -2 : CIP of Chamber to Cyclone Duct.

C] CLEANING CYCLE -3 : CIP of Main Cyclone

The CIP operation is carried out Zone wise in following zones

Cleaning time being easily adjustable, can optimize the cleaning cycle time

CIP systems can be customized to meet the specific needs of each application. For example, the type of cleaning solution, the cleaning temperature, and the cleaning time can all be adjusted.

CIP systems can also be equipped with sensors to monitor the cleaning process and ensure that it is completed successfully.

CIP systems offer a number of advantages over traditional manual cleaning methods, including:

Reduced labor costs: CIP systems can automate the cleaning process, which can help to reduce labor costs.

Improved cleaning efficiency:CIP systems can clean equipment more efficiently than manual cleaning methods. This is because CIP systems can use higher temperatures and pressures, and they can clean all surfaces of the equipment, including those that are difficult to reach by hand.

Improved product quality: CIP systems can help to improve product quality by ensuring that equipment is clean and sanitary. This is important in industries such as food and Herbal, Probiotech and pharmaceutical, where even small levels of contamination can have serious consequences.

Reduced environmental impact: CIP systems can help to reduce the environmental impact of cleaning operations by reducing the use of water and chemicals.

Overall, automatic cleaning-in-place systems are a valuable tool for businesses in a wide variety of industries. They can help businesses to improve their efficiency, reduce their costs, and produce high-quality products.

|

AKSH ENGINEERING SYSTEMS (P) LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |