MCC-ICP-PLC-SCADA-DCS And Instrumentation Automation

Product Details:

- Product Type PLC-SCADA-DCS And Instrumentation Automation

- For Use In Industrial

- Click to View more

MCC-ICP-PLC-SCADA-DCS And Instrumentation Automation Price And Quantity

- 1 Unit

MCC-ICP-PLC-SCADA-DCS And Instrumentation Automation Product Specifications

- PLC-SCADA-DCS And Instrumentation Automation

- Industrial

MCC-ICP-PLC-SCADA-DCS And Instrumentation Automation Trade Information

- 10 Unit Per Month

- 1 Week

Product Description

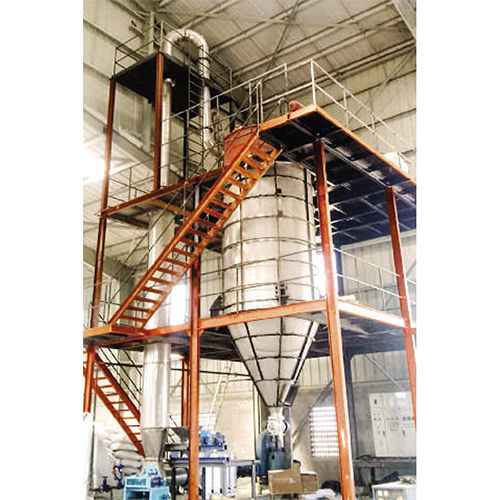

For the automated running of industrial drying and evaporation operations, AKSH provides a full automation solution. The automation suite consists of DCS, MCC, ICP, PLC, and SCADA. Instruments and controls, based on control configurations, come next. For electrical, instrumentation, and PLC design, installation, and commissioning, the business has an internal staff of its own. Moreover, AKSH has already offered a few unique features including cable-free panels and remote operation.

Instrumentation automation systems typically consist of the following components:

Drives/Invertors- Invertor are used to control speed /RPM of the equipment’s to control ,air flow ,feed flow, Pressure etc.

Level Sensors: Sensors are used to measure the physical characteristics of a process, such as Tank level, to control over flow wastage and smoot operation and level indication to system etc

Actuators: Actuators are used to control the physical characteristics of a process, such as the position of a valve or the speed of a motor.

Controllers: Controllers are used to process the data from the sensors and send signals to the actuators to control the process.

Pressure Transmitters- Are used to auto control of air quantity ,required for the systems between 02 fans ,for dryers,

The complexity of an instrumentation automation system varies based on the requirements of the particular industrial process. While big systems can contain hundreds or even thousands of sensors and actuators, simple systems might simply have a small number of these components.

Numerous software tools are usually used for programming instrumentation automation systems. The relationships between the sensors, actuators, and controllers can be defined by users using these tools. The industrial process can be automatically monitored and controlled by the system once it has been programmed.

Numerous software tools are usually used for programming instrumentation automation systems. The relationships between the sensors, actuators, and controllers can be defined by users using these tools. The industrial process can be automatically monitored and controlled by the system once it has been programmed.

Instrumentation automation has a number of benefits, including:

Improved efficiency: Instrumentation automation can help to improve the efficiency of industrial processes by reducing the amount of manual intervention required.:

Increased safety: Instrumentation automation can help to improve the safety of industrial processes by reducing the risk of human error.

Improved quality: Instrumentation automation can help to improve the quality of industrial products by ensuring that the process is consistently controlled within the desired parameters.

Reduced costs: Instrumentation automation can help to reduce the costs of industrial production by improving efficiency and reducing waste.

Overall, instrumentation automation is a valuable tool for businesses in a wide variety of industries. It can help businesses to improve their efficiency, safety, quality, and costs.

Here are some specific examples of how instrumentation automation is used in different industries:

Manufacturing :

Vehicles, chemicals, and food items are just a few of the produced goods whose production is managed via instrumentation automation. It is used, for instance, to regulate the flow of materials on assembly lines, the pressure in hydraulic presses, and the temperature of ovens.

|

AKSH ENGINEERING SYSTEMS (P) LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |