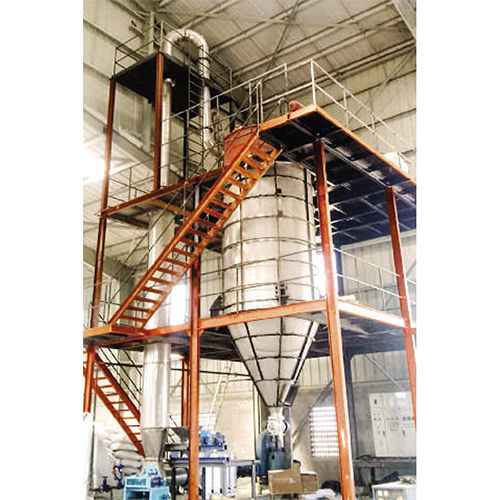

Zero Liquid Industrial Effluent Discharge Plant

Product Details:

- Type Zero Liquid Discharge Plant

- Material Stainless Steel

- Computerized No

- Automatic Grade Semi-Automatic

- Drive Type Electric

- Voltage 220-240 Volt (v)

- Color Silver

- Click to View more

Zero Liquid Industrial Effluent Discharge Plant Price And Quantity

- 3000000 INR/Unit

- 1 Unit

Zero Liquid Industrial Effluent Discharge Plant Product Specifications

- Electric

- 1 year

- Stainless Steel

- Zero Liquid Discharge Plant

- 220-240 Volt (v)

- Silver

- Semi-Automatic

- No

Zero Liquid Industrial Effluent Discharge Plant Trade Information

- 50 Unit Per Month

- 10 Days

Product Description

The term "zero liquid discharge" (ZLD) refers to a method of treating wastewater that leaves no liquid effluent in the environment and allows for safe disposal or reuse. ZLD plants are generally utilized in industries where hazardous materials or highly concentrated wastes are present.

Evaporation

The process of turning water from a liquid into a gas is called evaporation. The wastewater is heated to a temperature where water evaporates in order to do this. Following evaporation, the steam is condensed and collected as clean water.

Crystallization

The process of creating crystals in order to extract solids from a liquid solution is known as crystallization. Concentrating the fluid until the solids precipitate out of it accomplishes this. After that, the crystals can be gathered and dried.

The process of eliminating moisture from a solid material is called spray drying. The substance is heated to a temperature where the moisture evaporates in order to do this. After then, the dried material can be gathered, put to use, or disposed of.To lower the cost of per-liter effluent drying, we can utilize any high-calorific waste, such as coal, white coal, and so on, in this heating medium.

Drying

The process of drying is what takes the moisture out of a solid material. The substance is heated to a temperature where the moisture evaporates in order to do this. After then, the dried material can be gathered, put to use, or disposed of.

Benefits of ZLD plants

ZLD plants offer a number of benefits, including:

Reduced environmental impact: ZLD plants help to reduce the environmental impact of industrial wastewater by eliminating liquid effluent discharge. This can help to protect water resources and reduce pollution.

Water conservation: ZLD plants help to conserve water by recycling and reusing wastewater. This can be especially important in areas with limited water resources.

Reduced disposal costs: ZLD plants can help to reduce waste disposal costs by eliminating the need to dispose of liquid effluent. This is because the ZLD process concentrates the solids in the wastewater, which can then be disposed of more efficiently.

ZLD plants are used in a wide variety of industries, including:

Chemical industry

The chemical industry is a vast and diverse industry that produces a wide range of products, from basic chemicals like fertilizers and acids to specialty chemicals like pharmaceuticals and plastics. The chemical industry is also a major user of water, and wastewater from chemical plants can contain a variety of pollutants, including heavy metals, organic compounds, and hazardous materials.

Pharmaceutical industry

The pharmaceutical industry is a highly regulated industry that produces a wide range of products, from over-the-counter medications to prescription drugs. The pharmaceutical industry is also a major user of water, and wastewater from pharmaceutical plants can contain a variety of pollutants, including active pharmaceutical ingredients (APIs), antibiotics, and hormones.

Food and beverage industry

The food and beverage industry is a vast and diverse industry that produces a wide range of products, from fresh produce to processed foods to packaged beverages. The food and beverage industry is also a major user of water, and wastewater from food and beverage plants can contain a variety of pollutants, including organic matter, nutrients, and pathogens.

Mining industry

The mining industry is a major user of water, and wastewater from mining operations can contain a variety of pollutants, including heavy metals, acids, and sediments. Zero liquid discharge (ZLD) plants are a type of wastewater treatment system that can remove pollutants from wastewater to a point where it can be reused or safely discharged to the environment without any liquid effluent. ZLD plants are a valuable tool for the mining industry because they can help businesses to reduce their environmental impact, conserve water, and reduce their waste disposal costs.

Oil and gas industry

Produced water is the wastewater that is generated during oil and gas production. It can contain a variety of pollutants, including hydrocarbons, heavy metals, and salts. ZLD plants can be used to treat produced water to remove these pollutants and produce clean water that can be reused in the production process or safely discharged to the environment.

Power generation industry

Power plants generate a variety of wastewater streams, including cooling tower blowdown, flue gas desulfurization (FGD) wastewater, and boiler blowdown. These wastewater streams can contain a variety of pollutants, including heavy metals, salts, and acids. ZLD plants can be used to treat these wastewater streams to remove these pollutants and produce clean water that can be reused in the power generation process or safely discharged to the environment.

Textile industry

The textile industry is a major user of water, and wastewater from textile plants can contain a variety of pollutants, including dyes, heavy metals, and organic matter. Zero liquid discharge (ZLD) plants are a type of wastewater treatment system that can remove pollutants from wastewater to a point where it can be reused or safely discharged to the environment without any liquid effluent. ZLD plants are a valuable tool for the textile industry because they can help businesses to reduce their environmental impact, conserve water, and reduce their waste disposal costs.

Pulp and paper industry

The pulp and paper industry is a major consumer of water, and its wastewater can contain a variety of pollutants, including dissolved solids, organic matter, and chemicals. Zero liquid discharge (ZLD) plants are a type of wastewater treatment system that can remove pollutants from wastewater to a point where it can be reused or safely discharged to the environment without any liquid effluent. ZLD plants are a valuable tool for the pulp and paper industry because they can help businesses to reduce their environmental impact, conserve water, and reduce their waste disposal costs.

|

AKSH ENGINEERING SYSTEMS (P) LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |