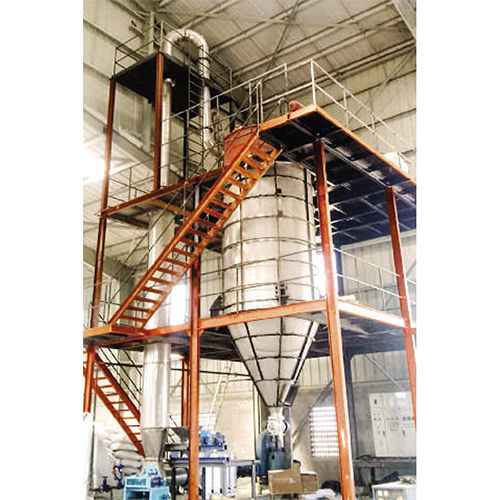

Industrial Continuous Fluid Bed Dryers

Product Details:

- Heat Source Electric

- Usage Industrial

- Material Steel

- Technology Normal

- Warranty Yes

- Click to View more

Industrial Continuous Fluid Bed Dryers Price And Quantity

- 1 Unit

Industrial Continuous Fluid Bed Dryers Product Specifications

- Electric

- Steel

- Yes

- Normal

- Industrial

Industrial Continuous Fluid Bed Dryers Trade Information

- Cash in Advance (CID)

- 50 Unit Per Month

- 10 Days

- All India

Product Description

FAQs of Industrial Continuous Fluid Bed Dryers:

Q: What is the material used for the Industrial Continuous Fluid Bed Dryers?

A: The dryers are constructed with high-quality steel material for durability and longevity.Q: Does the product come with a warranty?

A: Yes, the product comes with a warranty for added peace of mind.Q: What is the heat source for these dryers?

A: The heat source for these dryers is electric, providing efficient and reliable performance.Q: What type of technology is used in these dryers?

A: The technology used is normal, making it easy to operate and maintain.Q: What is the primary usage of these dryers?

A: These dryers are designed for industrial usage and are suitable for various applications.

Engineering Aksh Industrial dryers that use a fluidized bed of inert particles to dry materials are known as continuous vibratory or static fluid bed dryers. The moist cake, with a moisture content of 10–15%, is put into the dryer and hangs there in a hot air stream. The material is released from the dryer as a dry powder after the water has been evaporated by the hot air. The gentle drying procedure, excellent product quality, and high drying efficiency of Aksh Engineering Continuous Fluid Bed Dryers are well-known.

Continuous fluid bed dryer of static ,vibratory type are ideal for drying free flowing crystals, powders granules and extruded products.

In the vibrating fluid bed dryer, vibration transmitted by vibrantly motors are used to supplements the fluidizing air.

AKSH offers closed loop fluid bed dryer for solvent laden feed or where the feed can be oxidized in pressure of air, The fluid bed dryer capacities vary from 100 kg/hr to 5000 kg/hr

Aksh Engineering Continuous Fluid Bed Dryers offer a number of advantages over other types of dryers, including:

High drying efficiency: Continuous fluid bed dryers are very efficient at drying materials. This is because the fluidized bed provides a large surface area for the material to be exposed to the hot air.

High product quality: Continuous fluid bed dryers can produce products with a high degree of uniformity and consistency. This is because the fluidized bed mixes the material evenly and prevents the formation of agglomerates. And maintaining structure of particles

Wide range of applications: Continuous fluid bed dryers can be used to dry a wide range of materials, including food , Coconut powder ,Fungcide, Herbicide, Agri, Fertilizer, products, pharmaceuticals intermediates , chemicals, etc

Customizable designs: Aksh Engineering Continuous Fluid Bed Dryers can be customized to meet the specific needs of each customer. This includes factors such as the size of the dryer, the type of fluid bed, and the type of heating system. MOC selection heating media selection. And Final Powder cooling with normal ambient and if required Dehumidifier air

In addition to the above advantages, Aksh Engineering Continuous Fluid Bed Dryers are also known for their:

Durable construction: Aksh Engineering Continuous Fluid Bed Dryers are built to last. They are made from high-quality materials and components, and they are designed to withstand the harsh operating conditions of an industrial dryer.

Easy to operate and maintain: Aksh Engineering Continuous Fluid Bed Dryers are relatively easy to operate and maintain. They are equipped with user-friendly controls and they are designed to be easy to clean and maintain.

Overall, Aksh Engineering Continuous Fluid Bed Dryers are a valuable tool for businesses in a wide variety of industries. They can help businesses to improve their production efficiency, produce high-quality products, and reduce their costs.

Here are some specific examples of how Aksh Engineering Continuous Fluid Bed Dryers are used in different industries:

Food and beverage: Continuous fluid bed dryers are used to dry milk powder, coffee, and spices, Vegitable powder cooling and conveying, Coffee beans are dried to reduce their moisture content and improve their flavor. Spices are dried to preserve their flavor and aroma.

Pharmaceutical: Continuous fluid bed dryers are used to dry Pharma intermediate, vitamins powders , are dried to improve their handling and storage properties.

Chemical: Chemical:Continuous fluid bed dryers are used to dry detergents, soaps, and fertilizers.. Fertilizers are dried to improve their storage and handling properties.

Other industries: Continuous fluid bed dryers are also used in a variety of other industries, such as ceramics, minerals, metals,

A vast range of sectors can make use of the adaptable and effective drying technology provided by Aksh Engineering Continuous Fluid Bed Dryers. Compared to other dryer kinds, they provide a variety of benefits such high drying efficiency, high-quality products, a gentle drying process, a broad range of applications, and customizable designs.

|

AKSH ENGINEERING SYSTEMS (P) LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |