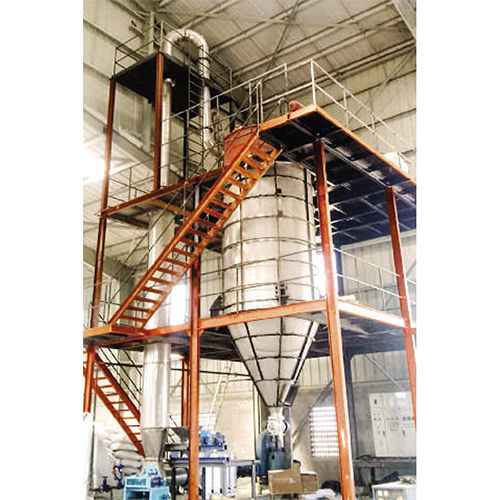

Industrial Rotary Disc Atomization

Product Details:

- Type Rotary Disc Atomization

- Material Stainless Steel

- Computerized No

- Automatic Grade Semi-Automatic

- Control System Human Machine Interface

- Drive Type Electric

- Click to View more

Industrial Rotary Disc Atomization Price And Quantity

- 2500000 INR/Unit

- 1 Unit

Industrial Rotary Disc Atomization Product Specifications

- No

- Rotary Disc Atomization

- Electric

- Stainless Steel

- Human Machine Interface

- Semi-Automatic

Industrial Rotary Disc Atomization Trade Information

- 50 Unit Per Month

- 10 Days

Product Description

Industrial Rotary Disc Atomization is a process used primarily in spray drying and similar applications where liquids are transformed into droplets for rapid drying or particle formation. Its ability to provide precise control over droplet size and distribution makes it indispensable in industries requiring consistent product quality and performance. This is suitable for a wide range of viscosities and liquid compositions, from water-like solutions to highly viscous materials. Industrial Rotary Disc Atomization is a versatile and efficient method for transforming liquid feedstocks into fine droplets, widely applied in spray drying, particle coating, chemical processing, and environmental technologies.

One of India's top producers of rotary disc atomizers is Aksh Engineering. Spray dryers employ rotary disc atomizers to turn liquids or slurries into dry particles. Rotating disc atomizers made by Aksh Engineering are renowned for their excellent performance, longevity, and quality. A revolving disc with several holes in it makes up a rotary disc atomizer. Once the liquid or slurry reaches the disc's center, it is forced through the holes by the revolving disc's centrifugal force. As a result, a thin mist of droplets is produced, which the spray drier uses to dry.

Centrifugal energy is used in rotary disc atomization, where feed is introduced at the center of a fast-rotating wheel. The feed moves toward the wheel's edge, where it accelerates and splits into microscopic droplets. When the heated air dries these droplets, they turn into powders that flow freely. With pride, AKSH provides the entire line of rotary atomizer spray dryers.

In accordance with customer requirements, Aksh has also designed several types and modules of atomizer wheels, such as [a] High BD powder, [b] Larger particle size powder, and [c] High solid maximum up to 70% can take load. [d] Wheels with different coatings also experience less wear and tear.

The wheel designs include the square hole, straight hole, umbrella wheel, high bulk density wheel, and curved vane with diameters of 60, 100, 175, 200, 350, and 400 mm. The feed rates at which the AKSH Atomizer operates range from 10 kg/hr to 15 000 kg/hr.

Advantages of Rotary Disc Atomization.

Rotary disc atomizers offer a number of advantages, including:

High drying efficiency: Rotary disc atomizers can produce very small droplets, which dry very quickly. This results in high drying efficiency.

Wide range of droplet sizes: Rotary disc atomizers can produce a wide range of droplet sizes, depending on the design of the atomizer and the operating conditions. This allows for flexibility in the spray drying process.

Durability: Rotary disc atomizers are very durable and can withstand the harsh operating conditions of a spray dryer.

Uniform droplet distribution: Rotary disc atomizers can produce a very uniform distribution of droplets, which is important for producing high-quality spray dried products.

Scalability: Rotary disc atomizers are available in a wide range of sizes, from small laboratory units to large industrial units. This makes them suitable for a wide range of applications.

Applications of Rotary Disc Atomization

Rotary disc atomizers are used in a wide variety of applications, including:

Food and beverage: Herbal, vegetable, synthetic, and natural food coloring, herbicides and fungicides, sulfur WDG, PPT silica, rice silica, microcrystalline cellulose (MCC), beverages, pharmaceutical intermediate chemicals, and textiles are all produced using rotary disc atomizers. Take Natural Products, Pharmaceutical Industry, and Alcohol Plants items, such as coffee, powdered milk, baby formula, seasonings, and spices.

Pharmaceutical: Rotary disc atomizers are used to produce a wide range of pharmaceutical Bulk drugs products, including antibiotics, vitamins, hormones, and enzymes Solvent base product.

|

AKSH ENGINEERING SYSTEMS (P) LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |