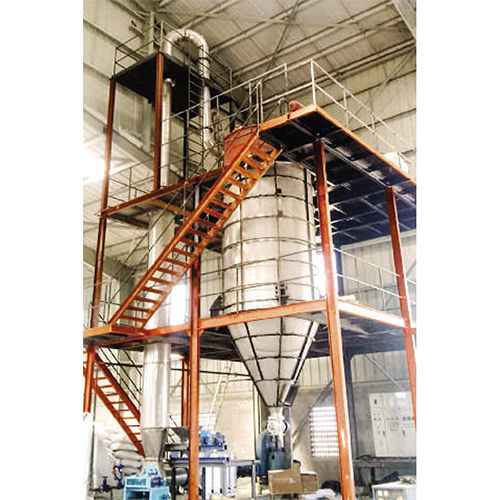

SFD Swirl Agitated-Spin Flash Dryers

Product Details:

- Usage Industrial

- Product Type Spin Flash Dryers

- Color Silver

- Material Stainless Steel

- Voltage 220-240 Volt (v)

- Warranty 1 Year

- Click to View more

SFD Swirl Agitated-Spin Flash Dryers Price And Quantity

- 200000 INR/Unit

- 1 Unit

SFD Swirl Agitated-Spin Flash Dryers Product Specifications

- 220-240 Volt (v)

- Industrial

- Stainless Steel

- 1 Year

- Silver

- Spin Flash Dryers

SFD Swirl Agitated-Spin Flash Dryers Trade Information

- 10-15 Days

Product Description

The SFD Swirl Agitated-Spin Flash Dryers is an advanced type of flash dryer designed for the efficient drying of slurries, pastes, or sticky materials. The dryer is equipped with a specially designed agitator or rotor that creates a swirling motion within the drying chamber. This swirling motion enhances heat and mass transfer, ensuring thorough mixing of the material and promoting uniform drying. It combines the principles of swirl agglomeration and flash drying to achieve rapid moisture removal and particle size control. SFD Swirl Agitated-Spin Flash Dryers innovative design and operational advantages make it a preferred choice for manufacturers seeking enhanced performance and productivity in their drying processes.

Swirl Agitated (Spin) by Aksh Engineering One kind of flash dryer is a swirl agitator, which forms a fluidized bed of material inside the drying chamber. In addition to minimizing agglomeration formation, this fluidized bed enables fast and even drying of the feed material. Heat-sensitive materials and sticky, thixotropic cakes are the perfect applications for Aksh Engineering Swirl Agitated (Spin) Flash Dryers. They are also excellent for drying items that contain a lot of moisture.

Thixotropic cakes that are sticky are best dried with Swirl Agitated (Spin) Flash Dryers. The wet feed is delivered into these dryers in a fluidized bed of material that is whirling. The bed is continuously stirred by an agitator that is fixed at the bottom. Adequate Residence Time of the final product can be controlled in this Dryer. if cake is solved Laden, then closed loop Designs of the swirl Agitated (spin) Flash Dryer operating with Nitrogen as the heating media are available.

AKSH offers Swirl Agitated (spin) Flash Dryers with Feed capacities ranging from 50 kg/hr to 6000 kg/hr.

Advantages of Aksh Engineering Swirl Agitated (Spin) Flash Dryers

Aksh Engineering Swirl Agitated (Spin) Flash Dryers offer a number of advantages, including:

High drying efficiency: Swirl agitated (spin) flash dryers can dry materials very quickly and efficiently. This is because the swirl agitator helps to create a fluidized bed of material, which increases the surface area of the material and allows it to dry more quickly.

High product quality: Swirl agitated (spin) flash dryers can produce products with a high degree of uniformity and consistency. This is because the swirl agitator helps to mix the feed material evenly and prevent the formation of agglomerates.

Gentle drying process: Swirl agitated (spin) flash dryers use a gentle drying process that preserves the quality of the product. This is because the feed material is exposed to the hot gas for a very short period of time, which minimizes the risk of degradation.

Wide range of applications Swirl agitated (spin) flash dryers can be used to dry a wide range of materials, including sticky, thixotropic cakes, as well as materials that are sensitive to heat. They are also well-suited for drying materials with a high moisture content.

Customizable designs: Aksh Engineering Swirl Agitated (Spin) Flash Dryers can be customized to meet the specific needs of each customer. This includes factors such as the size of the dryer, the type of swirl agitator, and the type of heating system.

Durable construction: Aksh Engineering Swirl Agitated (Spin) Flash Dryers are built to last. They are made from high-quality materials and components, and they are designed to withstand the harsh operating conditions of a flash dryer.

Easy to operate and maintain: Aksh Engineering Swirl Agitated (Spin) Flash Dryers are easy to operate and maintain. They are equipped with user-friendly controls and they are designed to be easy to clean and maintain.

Applications of Aksh Engineering Swirl Agitated (Spin) Flash Dryers

Aksh Engineering Swirl Agitated (Spin) Flash Dryers are used in a wide variety of industries, including:

Food : Swirl agitated (spin) flash dryers are used to dry a variety of food products, including powdered spices, and seasonings.

Pharmaceutical: Swirl agitated (spin) flash dryers are used to dry a variety of pharmaceutical Intermediate products, Exaple .

Chemical: Swirl agitated (spin) flash dryers are used to dry a variety of chemical products, including Dyes, Dyes intermediate like Vinyle sulphone , H acid ,Dasa, Dasda, fertilizers, and pesticides etc .

Plastic: Swirl agitated (spin) flash dryers are used to dry a variety of plastic products, including PVC powder, polyethylene powder, and polyester powder.

Other industries: Swirl agitated (spin) flash dryers are also used in a variety of other industries, such as minerals, metals, MCCP , and waste treatment.

|

AKSH ENGINEERING SYSTEMS (P) LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |