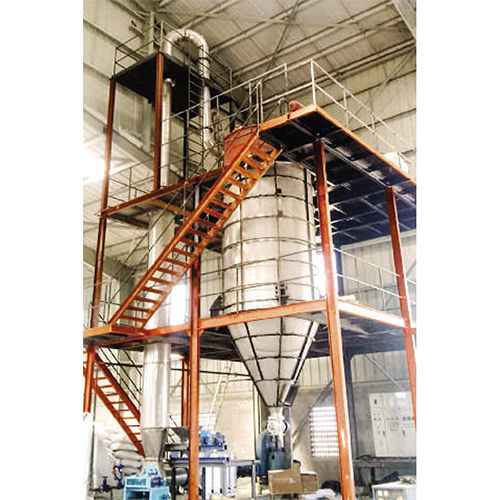

Industrial Rotary Dryers

Product Details:

- Usage Industrial

- Heat Source Electric

- Material Stainless Steel

- Technology Normal

- Warranty Yes

- Click to View more

Industrial Rotary Dryers Price And Quantity

- 1 Unit

Industrial Rotary Dryers Product Specifications

- Stainless Steel

- Industrial

- Normal

- Electric

- Yes

Industrial Rotary Dryers Trade Information

- Cash in Advance (CID)

- 50 Unit Per Month

- 10 Days

- All India

Product Description

FAQs of Industrial Rotary Dryers:

Q: What is the heat source for the Industrial Rotary Dryers?

A: The heat source for our Industrial Rotary Dryers is electric.Q: What material is used to construct the Industrial Rotary Dryers?

A: The Industrial Rotary Dryers are made of stainless steel for durability and resistance to corrosion.Q: What type of technology is used in the Industrial Rotary Dryers?

A: The Industrial Rotary Dryers utilize normal technology for efficient operation.Q: What is the warranty coverage for the Industrial Rotary Dryers?

A: Our Industrial Rotary Dryers come with a warranty for added peace of mind.Q: What is the intended usage for the Industrial Rotary Dryers?

A: The Industrial Rotary Dryers are designed for industrial applications.

Engineering Aksh A revolving drum is used by rotary dryers, a kind of industrial drier, to dry materials. They are renowned for their excellent drying efficiency, superior product quality, and heat-sensitive products (such as maize germs). They are also known for their high-temperature products (such as mines, fertilizers, cement, sulfur WDG, and drying processes).

Large capacity applications with an irregular particle size distribution in the feed are a perfect fit for rotary dryers. These dryers require little upkeep and are quite durable.

In essence, the Rotary Dryer is a spinning, slanted shell. Spirally placed lifters distribute the feed throughout the shell, directing it into a heated air stream. Girth gear tires are used to rotate the Rotary Dryer.

To prevent the leaking of products or air, special seals are used.

Aksh Engineering Rotary Dryers are used in a wide variety of industries, including:

Food and beverage Aksh Engineering Rotary Dryers are used to dry a variety of Coffee Seads, Coffee wastage having High cal value. and Sugar industries to dry waste products DDGS dryer , and in starch [maiz] Germs and spices.

Pharmaceutical: Aksh Engineering Rotary Dryers are used to dry a variety of pharmaceutical waste product

Chemical: Aksh Engineering Rotary Dryers are used to dry a variety of chemical products, such as fertilizers ,Herbicide,Mines, Cement

Minerals: Aksh Engineering Rotary Dryers are used to dry a variety of minerals, such as sand, gravel, and limestone.

Aksh Engineering Rotary Dryers offer a number of advantages over other types of dryers, including:

High drying efficiency: Aksh Engineering Rotary Dryers are very efficient at drying materials. This is because the rotating drum provides a large surface area for the materials to be exposed to the hot gas.

Durable construction: Aksh Engineering Rotary Dryers are built to last. They are made from high-quality materials and components, and they are designed to withstand the harsh operating conditions of an industrial dryer.

High product quality: Aksh Engineering Rotary Dryers can produce products with a high degree of uniformity and consistency. This is because the rotating drum mixes the materials evenly and prevents the formation of agglomerates.

Wide range of applications:Aksh Engineering Rotary Dryers can be used to dry a wide range of materials, including food products, pharmaceuticals, chemicals, minerals, and waste products.

Customizable designs: Aksh Engineering Rotary Dryers can be customized to meet the specific needs of each customer. This includes factors such as the size of the dryer, the type of drum, and the type of heating system.

Engineering Aksh Rotary Dryers are a versatile and efficient drying technology that can be used in a wide variety of industries. They offer a number of advantages over other types of dryers, such as high drying efficiency, high product quality, a gentle drying process, a wide range of applications, and customizable designs.

|

AKSH ENGINEERING SYSTEMS (P) LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |