Showroom

Spray dryers, operating on 220-415 volts AC, convert liquids into powders by atomizing them into a fine mist and drying with hot air. Their gray and white design includes lubricated systems for efficient operation. Common in food, pharmaceutical, and chemical industries, they ensure consistent quality and require regular maintenance for optimal performance.

The Sulphur WDG Plant, operating at 220-440 volts with an electric drive, is a semi-automatic system for sulfur grinding and nitrogen purging. This gray plant efficiently produces fine sulfur powders, preventing oxidation. Used in agriculture and chemicals, it offers controlled processing and consistent output with enhanced safety and quality.

Rotary Disc Atomization uses a stainless steel disc to transform liquids into droplets for rapid drying or particle formation. Operated semi-automatically with an electric drive and controlled via a Human Machine Interface, it is ideal for spray drying. It is widely used in industries like pharmaceuticals and food processing for consistent particle size and quality.

A Flash Dryer uses flash drying principles for rapid, efficient drying with minimal energy use. It features automated controls for enhanced efficiency and ease of operation, making it crucial in modern manufacturing. Its ability to boost productivity while maintaining product quality makes it ideal for various industrial applications.

The Cage Mill Flash Dryer, with an electric heat source and stainless steel build, excels in simultaneous grinding and drying. It uses a cage mill to pulverize materials while hot air rapidly dries them. Ideal for chemicals, food, and minerals, it offers reliable operation, precise temperature control, and easy maintenance.

The Swirl Agitated-Spin Flash Dryer, made of stainless steel and finished in silver, is used industrially for drying slurries, pastes, or sticky materials. Operating at 220-240 volts, it efficiently dries products with rapid, uniform results, making it ideal for industries like chemicals and food processing.

A Nozzle Atomization Spray Dryer converts liquid feed into powders or granules through precise atomization and drying. Essential for industries needing uniform, high-quality products, it controls particle size and moisture content efficiently. Operating with optimal energy use, it reduces costs while ensuring versatile and effective drying across varied sectors.

An Industrial Whole Egg Turnkey Plant is a complete facility for large-scale whole egg production, integrating egg reception, processing, and packaging. Designed for high-volume output, it meets food industry demands with efficient, scalable operations, ensuring product safety, quality, and consistency. It provides a comprehensive solution for the food processing sector.

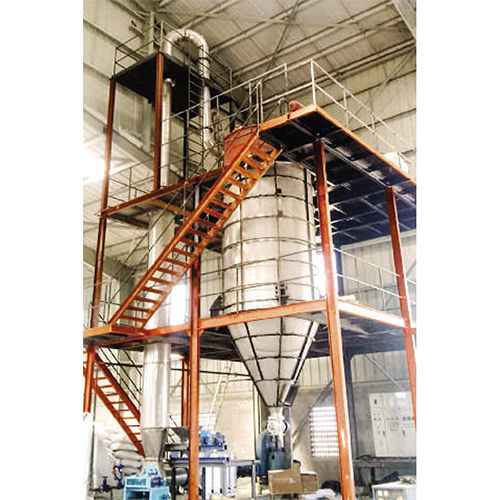

The Multistage Spray Dryer operates at 600°C, using coal, gas, wood, biomass, or natural fuels. With a power consumption of 200 HP and weighing 5000 kg, it features a width of 20 meters. It efficiently dries various materials in stages, ideal for industries requiring high-capacity, precise drying solutions.

Industrial Rotary Dryers are durable machines for drying granular materials, powders, and slurries across industries. Handling minerals, chemicals, and biomass, they operate continuously with large capacities. Designed for efficient heat transfer, they often feature heat recovery and insulation, coming in various sizes to meet diverse drying needs.

Continuous Fluid Bed Dryers efficiently dry granular, powdered, or crystalline materials, ensuring uniform drying and energy efficiency. Essential for modern manufacturing, they handle materials like pharmaceutical ingredients and fragile powders with precise control. Versatile and efficient, these dryers suit varied industries requiring continuous drying of diverse materials.

Pollution Control Systems are vital for reducing industrial emissions, managing waste, and meeting environmental regulations. Using advanced technologies, they promote cleaner operations, efficient resource use, and cost savings. By minimizing pollutants and protecting ecosystems, these systems ensure sustainable development and safeguard both human health and the environment.

|

AKSH ENGINEERING SYSTEMS (P) LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |